From handling raw materials to delivering finished product into the hands of your customers, you need reliable material handling solutions to keep you moving.

Whether you need to eliminate product touches, boost awareness or automate processes, Yale has what you need to reduce bottlenecks slowing down your operations.

Need help finding the right solution? Connect with our beverage experts or see our lift trucks in action.

Don’t let incidents, OSHA fines and downtime bring your operation to a screeching halt. Take action with operator awareness and product safety solutions to help mitigate risk across your facility.

Enhance awareness & stability

Promote awareness and help reduce incidents with Yale® Reliant, a technology suite that automatically adjusts lift truck performance based on real-time conditions.

- Detect tagged trucks and pedestrians in proximity (360˚)

- Monitor and detect objects in the path of travel and identify trucks/pedestrians out of line of sight

- Adjust travel speeds and hydraulic functions while maintaining truck stability

- Monitor forklift truck location, exclusion zones, lift height restrictions and more

Make beverage safety non-negotiable

Protect equipment against contamination and boost sanitation/disinfection on all touch points.

- Reduce bacteria absorption by using impenetrable materials

- Achieve greater transparency to help isolate concerns to reduce product loss

- Utilize food-grade lubricants that are non-toxic and USDA inspection ready

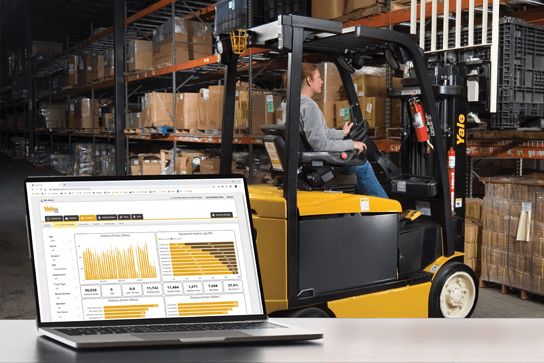

Operational transparency - forklift tracking

Get 20/20 vision into your operations. Experience real-time lift truck and operator utilization, and how they are performing with Yale Vision telematics.

- Impact camera option increases operator accountability

- Enforce OSHA pre-shift checklist completion

- Receive usage metrics, impact detection and alerts

- Restrict truck access to approved operators only

Nearly half (47%) of those in the beverage supply chain find the lack of skilled workers to be their greatest challenge. Your trucks must run at optimal performance, while providing ergonomic benefits to keep your operators at their peak.

Optimize labor resources

Don’t let labor shortages hold your operations hostage. Gain independence and reduce the risk of mishaps and maintenance costs from inexperienced operators.

- Improve retention by promoting skilled labor to more engaging roles

- Enhance picking accuracy and transport efficiency

- Reduce unnecessary product/facility damage

- Limit product touches and human error

- Provide greater obstacle and pedestrian detection

Promote supply chain productivity

Make the most out of scarce resources with simplified battery maintenance, charging and replacement processes to help increase uptime and productivity.

- Eliminate battery maintenance downtime

- Opportunity charge and reach up to 8 hours of continuous runtime

- Fully charge in 1-2 hours, no cool down needed

- Providing consistent power throughout discharge cycle

- Improve operator ergonomic seat position and comfort with increased head and leg room

Attract & retain forklift drivers

Give your drivers the confidence to move more cases easier, and in less time from trailer lift gates, across unforgiving terrain, and through narrow convenience store aisles.

- Helps reduce the physical stress to operator

- Gain confidence in tight spaces with the minimized footprint of the lithium-ion battery pack, 25% shorter than lead-acid battery packs

- Defy route and charging limitations to help reduce labor cost per case delivered, and help drivers achieve up to 11% greater productivity

- Allow your operators to handle multiple pallet shapes and sizes with a single fork configuration using a multiple load backrest

Best-in-class operations utilize more than 95% of available warehouse capacity. And, with beverage operations seeing 2-8% more new product introductions than the next leading category that means more SKUs to process, store and distribute.

Maximize capacity & increase throughput

Boost efficiency with lift trucks proven to reduce cycle times and increase cases moved per hour. With SKU counts climbing, space utilization and picking processes are being pushed to the brink.

Reduce pick times and improve order accuracy with the Yale end rider.

- Smart features to help shave seconds off tasks for greater throughput

- Precision pick allows control of speed and coast functions in both directions

- Service faster and as much as 50% less often, reducing downtime

Maneuver confidently in tight spaces with the Yale® three-wheel stand.

- Take products in and out of tight spaces with a turning radius that means business, taking maneuverability to the next level

- Keep operators working confidently with the Hi-Vis™ mast, giving them both visibility and rigidity

- Eliminate up to 65% of shock and vibration transmitted to the operator, an advantage of 17% more isolation over leading competitors with the Yale® Smart Ride Floor System

Achieve greater slotting capacity with the Yale® multi-level order picker.

- Use variable height picking processes to increase SKU capacity to help increase pick positions up to 400%, and slot capacity 140% within same footprint

- Place slower-moving SKUs above faster-moving ones for efficient access to frequently picked items

- Add case flow lanes to pick lines to accommodate more SKUs

Same-day delivery is becoming an expectation. To beat the competition and keep costs down, speed and agility are imperative.

Defy challenging terrain

Replenish your products in confidence across pothole-ridden parking lots, curbs, and door jams to meet increasing direct-store delivery demands.

- Empower your operators with features that increase greater maneuverability in tight spaces and on the lift gate

- Keep loads stable and secure with auxiliary traction and moveable load backrest

- Return empty with charging capabilities up to 2x faster and last longer with lithium-ion batteries

Resources & Support

Find the right truck for you application while discovering proven solutions and tactics beverage operators consider essential today.