WHITE PAPER

What to consider when buying a forklift

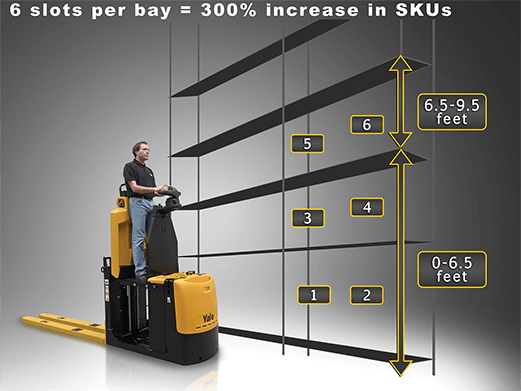

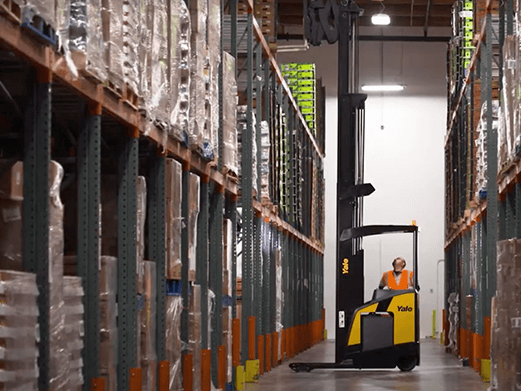

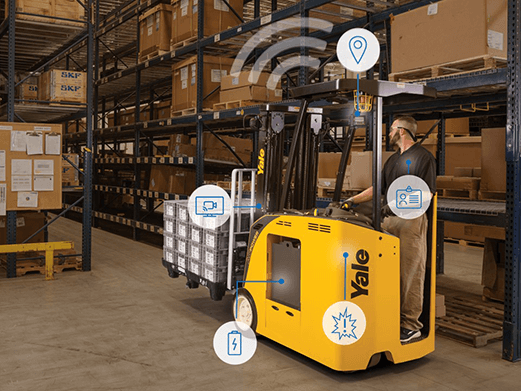

In warehouses and distribution centers, fast and accurate order fulfillment defines success, so it's important to prioritize capacity and picking efficiency. As SKU counts increase and order profiles change, racking and slotting systems that functioned adequately in the past may begin to compromise order fulfillment efficiency.