Clear the dock quickly

Automated receiving

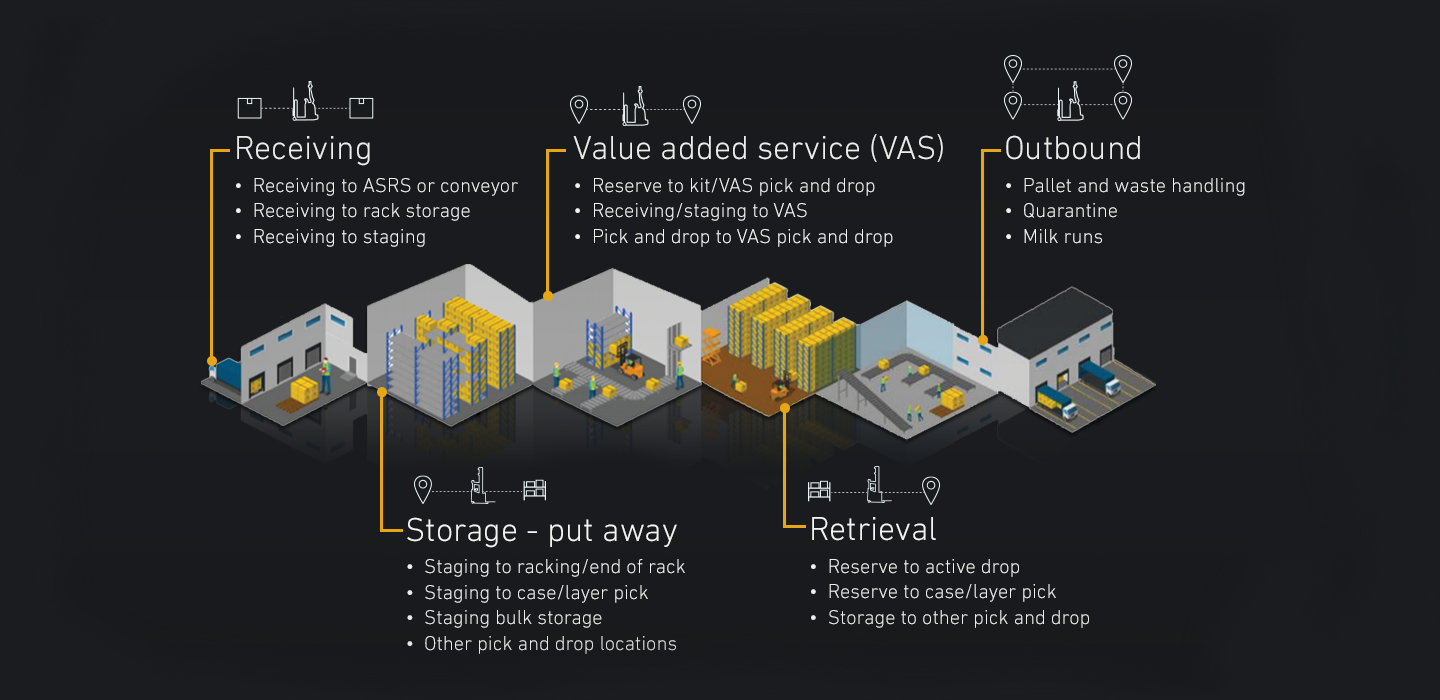

Receiving docks must quickly move incoming loads to make room for the next arrivals. Once pallets are offloaded from trailers, inspected, labeled and scanned, the warehouse management system (WMS) can trigger a robotic lift truck to pick them up and move them to a designated drop-off location, such as racking, AS/RS, conveyor or a staging area.