Mapping your warehouse is as simple as pressing “start” and manually navigating a single automated lift truck around your facility a couple of times. Once complete, the map is saved to all the automated lift trucks in your fleet.

Easy

No custom code or engineering required.

A drag-and-drop portal allows for implementation of automated lift trucks in as little as a day and gives you the control to make changes on the fly.

Cost effective

Automation without the up-front cost.

A frictionless rental model delivers financial flexibility and a clear return on your automated lift truck investment without a large capital outlay or hidden costs.

Reliable

Seamless support straight from the source.

Yale Relay™ is backed by the extensive Yale® dealer network for training, parts and maintenance to keep you up and running.

The automated lift truck portal

The user-friendly, drag-and-drop portal is central to Yale Relay automated lift trucks. It allows you to implement automated forklifts in your facility in as little as a day, and to make changes without expensive programming or software engineering resources.

To make route changes, just click on the waypoint you want to change and drag it to a new location. The system automatically calculates the turning radius for each automated lift truck for seamless navigation.

To add an additional automated lift truck to your automated fleet, simply pair the new truck to your network and enter its information. The assets window displays the new truck’s details once it’s added.

Managing automated lift truck traffic in your warehouse is as easy as drawing zones on the map to define where trucks can operate and cross paths. After the zones are set, a back-end algorithm handles traffic control for you.

Reliable technology, seamless support

Automated lift truck training, parts and service

A self-driving forklift solution won’t do your warehouse any good if it is unreliable or difficult to maintain. Some approaches to robotic forklifts involve struggling with disjointed integration, maintenance from multiple providers or long waits for offshore support. With Yale Relay automated lift trucks, a single, local source – your Yale dealer – provides training, parts and responsive service.

Frictionless rental model

Automate without a large capital outlay or hidden costs

Deploy automated lift trucks in your warehouse without the burden of ownership or long-term commitments. A frictionless rental provides a fast, hassle-free way to implement automation that rolls all costs into a single monthly or annual fee. A low barrier to entry lets you pilot the program with only one or two trucks, and the price includes coverage for software and hosting fees and ongoing platform improvements at no additional cost.

Automated lift truck frequently asked questions

Why are warehouses investing in automated lift trucks?

- Warehouse operations are investing in automated lift trucks to improve efficiency and productivity while lessening dependence on scarce labor. Automated lift trucks can also help reduce operating costs, help reduce accidents and avoidable damage and combat high operator turnover.

Aren’t automated lift trucks complex, time-consuming and labor-intensive to install and reprogram?

- Automating forklifts isn’t new. However, they are still in a relative infancy stage, and some operations have been hesitant to adopt because of misconceptions or sub-optimal experiences with other providers. Yale Relay was developed in direct consultation with customers to overcome traditional shortcomings of automation with a simple, dependable solution. The automated lift trucks are backed by a long history of innovation and corporate stability.

Are automated lift trucks safe?

- Yale Relay automated lift trucks are compliant with UL safety standards and adhere to the ANSI/ITSDF B56.5 safety standard and site-specific safety protocols. They can sense both ground level and suspended items, such as ladders hanging off a carrier.

What operations are the best candidates for automated lift trucks?

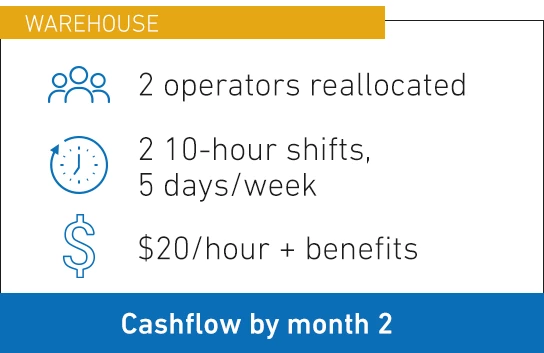

- Warehouses operating with multiple shifts, dedicated headcount and frequent indoor horizontal transport tasks with repeatable paths, like point-to-point material transfers, are particularly good candidates for automated lift trucks.

Where do automated lift trucks work?

- Automated lift trucks are well suited for indoor applications with clean, flat floors with less than a 3% incline. They are compatible with single-temperature operations with temperatures above 32 degrees Fahrenheit.

What type of floor surface is best for automated lift trucks?

- Warehouse floors should be flat and free of bumps or light reflection. Flooring should not be macadam or vinyl, due to static energy.

Do I need to modify my warehouse or facility infrastructure to accommodate automated lift trucks?

- In many cases, no. Yale Relay uses infrastructure-free navigation technology so there is no need to install targets, ground wires or reflectors or make other modifications. However, in some unique situations, an automation specialist might suggest installing flags or reflective materials.

Do automated lift trucks need to be monitored?

- Automated lift trucks are fully autonomous when performing programmed tasks. Individual trucks and fleets can be monitored through the cloud-based Yale Relay drag-and-drop portal across multiple facilities. Large fleets might have the need for a fleet supervisor, and, for recovery situations, an on-site floor supervisor is required for support.

How do automated lift trucks navigate?

- Yale Relay automated lift trucks use a simultaneous localization and mapping (SLAM) algorithm to map your facility and check the truck’s location on the map. They are equipped with a LiDAR system that determines the truck’s location and direction of travel.

How long does it take to map a facility?

- Yale Relay can map a facility in 2D within 15 minutes . With Yale Relay, mapping your facility is as easy as navigating the truck through your warehouse several times. Once the facility is mapped by one truck, the map can be saved to all the units in your fleet.

Do automated lift trucks interface with WMS and ERP systems?

- Yale Relay integrates with basic warehouse systems such as fire alarms and interactive input boxes. Integration with warehouse management systems and programmable logic controls will be available soon.

Can I adapt the automated technology to an existing lift truck?

- No, automated lift trucks are available for factory order only. There is not currently an aftermarket option available to convert manual lift trucks into automated lift trucks.

If a path change is needed, does a trained software engineer need to make the adjustment?

- No. The Yale Relay drag-and-drop portal gives you the control to make path changes easily without the need for custom code or engineering.

How does the truck switch from automated to manual mode?

- To take manual control, the operator can either push a button, step on the truck platform. The 3D camera system on Yale Relay trucks automatically checks for operator presence and prevents the truck from moving in automated mode when there is a person in the operator compartment.

Who provides service for automated lift trucks?

- Convenient service, training, parts and support for Yale Relay automated lift trucks is provided through the Yale dealer network.

What happens when the battery gets low or dies?

- Automated lift trucks are equipped with wireless automated charging. When the battery gets low, the truck automatically returns to a charging station and docks and charges on its own without the need for human intervention. You can program the truck to automatically return to a charging station when a certain threshold is met – for example, when the battery is depleted to 20% of its full charge. If automated charging is not selected, the truck stops where it is when the battery dies.

What happens if our network goes down?

- If the network goes down, the truck drives to its next waypoint and stops. It then resumes its job when network connectivity is restored.

How long does integration take?

- The user-friendly Yale Relay drag-and-drop portal allows integration in as little as a day.

Are automated lift trucks expensive to implement?

- With available leasing programs, automated lift trucks can be implemented with little upfront cost and no hidden fees. Plus, you can start with as few as one or two trucks, so you can scale your automated lift truck investment to suit the requirements of your warehouse.

Can I lease automated lift trucks?

- Yes. The Yale Relay frictionless rental model provides financial flexibility and a clear return on investment, allowing you to deploy automated lift trucks in your warehouse without a large capital outlay or hidden costs.

How many automated lift trucks are needed to justify the system?

- You can implement automation in your warehouse with as few as one or two automated lift trucks and scale the fleet based on your business requirements.

How long do automated lift trucks last?

- In most cases, an automated lift truck can last longer than a standard truck due to the abuse often associated with manual trucks. Typically, automated lift trucks have a useful life of four to five years with proper maintenance.

Resources

Fact sheet

Autonomous server transport for data centers

See how automated lift trucks can help data centers improve security, prioritize safety and enhance efficiency when moving servers.

Webinar

Planning for automated lift trucks

Gain academic and industry perspectives on how to successfully plan for automated lift trucks in your warehouse.

White paper

A practical approach to automated lift trucks

Learn the steps you can take to prepare your warehouse for successful implementation of automated lift trucks.